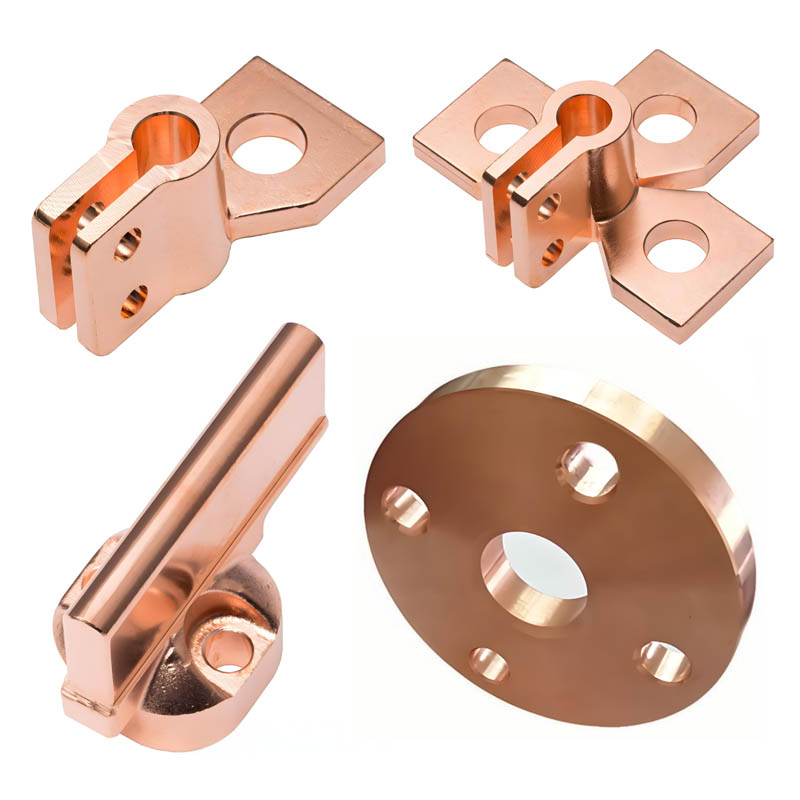

Copper alloy forgings

What are Copper Alloy Forgings?

Copper alloy forgings are components crafted from copper-based alloys that have been shaped through the forging process, which involves applying compressive forces to heated metal.This technique enhances the material's strength and durability, making it suitable for demanding applications.

History of Copper Alloy Forgings:

The history of copper alloy forgings dates back to ancient times when pure copper was first used around 10,000 BC.

The development of bronze—an alloy of copper and tin—around 3000 BC marked a significant advancement, leading to the Bronze Age and the creation of durable tools and weapons through forging techniques.

Throughout the Middle Ages and into the Industrial Revolution, advancements in metallurgy and mechanization improved forging processes.

The demand for high-performance materials during WWII further spurred innovation, resulting in the modern use of copper alloy forgings across various industries, including aerospace, electrical engineering, and automotive applications, where their strength, corrosion resistance, and conductivity are highly valued.

Types of Copper Alloys: Copper, Brass, and Bronze

| Property | Copper | Brass | Bronze |

|---|---|---|---|

| Composition | Pure metal (Cu) | Copper + Zinc (55-95% Cu) | Copper + Tin (plus other elements) |

| Color | Reddish-brown | Yellowish-gold | Reddish-brown to golden |

| Conductivity | Excellent (highest among the three) | Good (lower than copper) | Moderate |

| Malleability | Very high | High | Moderate to low |

| Corrosion Resistance | Good | Good | Excellent |

| Strength | Moderate | High | High |

| Applications | Electrical wiring, plumbing | Musical instruments, fittings | Bearings, sculptures, tools |

Why Choose Copper Alloy Forgings?

1. Excellent Electrical and Thermal Conductivity

Many copper alloys maintain excellent conductivity, making them suitable for electrical applications. This is crucial for components like connectors, terminals, and circuit elements where efficient energy transfer is essential.

2. Corrosion Resistance

Copper alloys are highly resistant to corrosion, particularly in marine and industrial environments. This resistance extends the lifespan of components, reducing maintenance and replacement costs.

3. Recyclability

Copper alloys are highly recyclable without losing their essential properties, contributing to sustainable manufacturing practices. This is a significant advantage over some materials that are less environmentally friendly.

4. Aesthetic Appeal

Copper and its alloys can have a visually appealing appearance, making them suitable for decorative applications in addition to functional ones.

Copper alloy forging parts play a crucial role in many industries, including electrical, automotive, plumbing, marine, and aerospace. Their unique properties—such as high electrical and thermal conductivity, corrosion resistance, and strength—make them essential for applications that demand reliable performance. Understanding the advantages of copper alloys helps manufacturers and engineers select the right materials for their specific needs, ensuring optimal functionality and longevity.

Contact Us

E-mail: [email protected]

WeChat: 18332109035

Whatsapp: 18332109035

Add: Shi Jiazhuang, He Bei Province

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry